News

Popular keywords

News

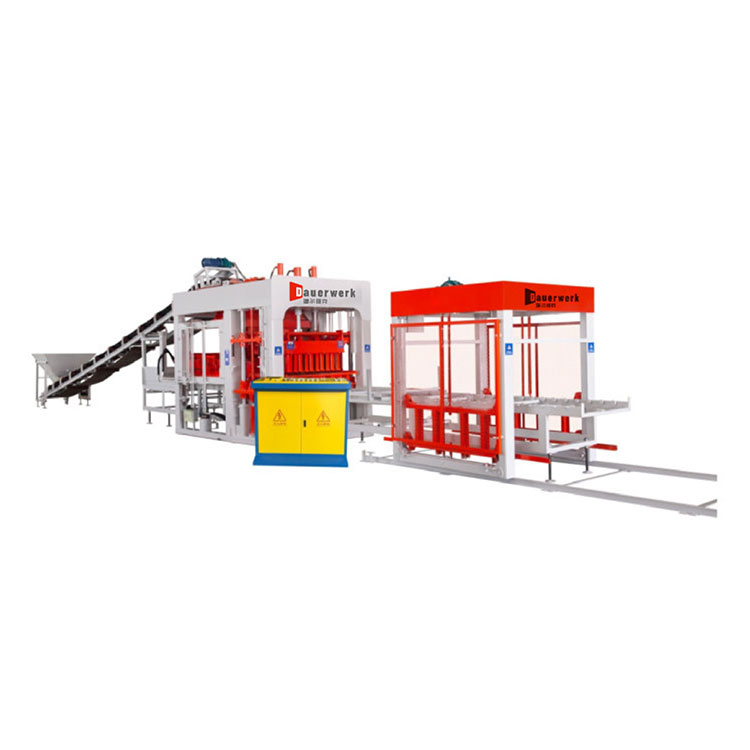

Current Location:Home >News>Industry NewsWhat are the technical advantages of block making machines?

1. Compared with traditional clay brick machines, the raw materials of block forming machines can be selected from industrial waste slag: coal fly ash, coal gangue, slag, smelting slag and various tailings slag as the main raw materials, which is more environmentally friendly, energy-saving and waste recycling.

2. The block forming machine adopts three-bar up and down pressure forming in one time. After forming, it can be stacked immediately without a brick support plate. It is the latest model in domestic block bricks.

3. The standard bricks produced by the block forming machine are low-cost and profitable. Taking into account various necessary costs, the cost of each standard brick is 9 cents, and the market price is 2-3 times this.

4. The body of the block forming machine is made of high-precision, high-strength castings and special welding technology and materials, with good rigidity, vibration resistance and long service life.

5. The block forming machine adopts hydraulic pressure forming with table mold vibration and reciprocating guide feeding device, with short forming cycle, high production efficiency, high quality and compact strength of blocks and precise size.

6. The block forming machine adopts mechanical, electrical and hydraulic integration technology to make each cycle of the equipment consistent, so the forming output is high, the stability is high and the scrap rate is low.

7. The block forming machine is multi-purpose. By changing the mold, it can produce porous bricks, hollow blocks, curbstones, pavement bricks, grass and tree bricks, lattice bricks and other cement products of different specifications.

8. The program can be compiled according to production needs to realize manual, semi-automatic, fully automatic and other action operations.

Next Article:How to use a blender safely? Return