Products

Recommended

Products

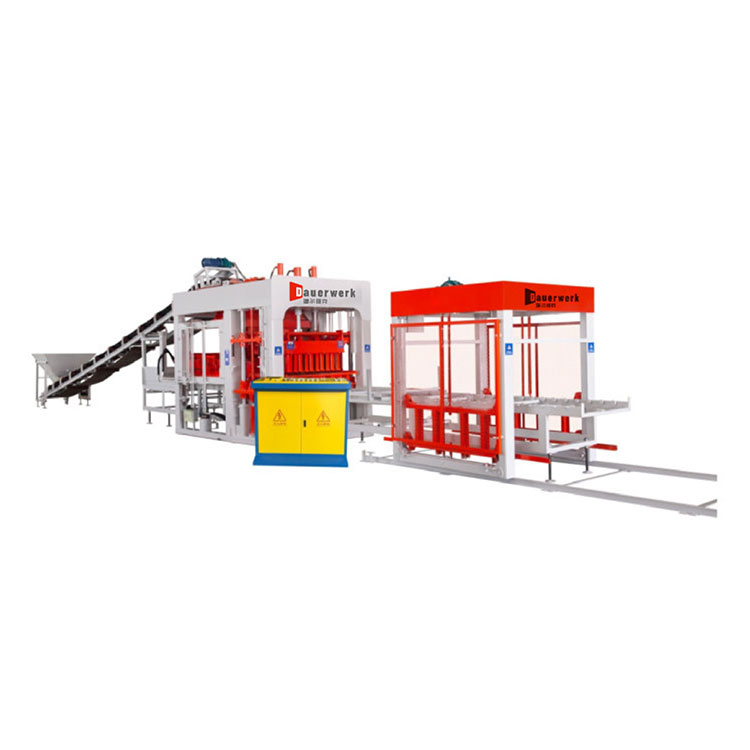

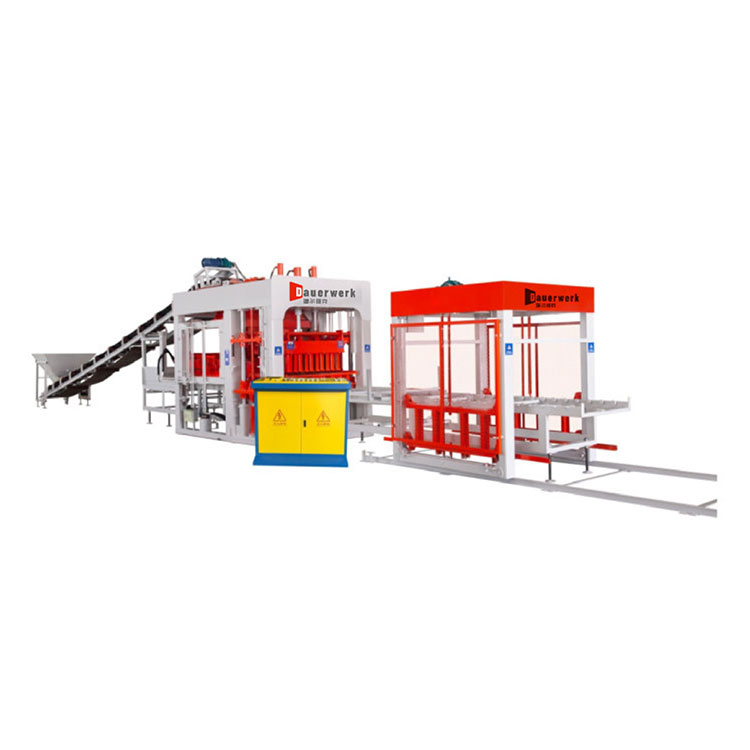

Current Location:Home > Products>Molding MachineDW Series automatic concrete block forming machine

Raw materials: sand, gravel, cement, and a large amount of fly ash, slag, steel slag, coal grinding stone, ceramsite, perlite and other industrial wastes can be added.Product Description

Raw materials: Sand, gravel, cement, fly ash, slag, steel slag, coal grinding stone, ceramsite, perlite and other industrial waste materials can be added in large quantities.

Uses: Production of various exterior wall blocks, interior wall blocks, flower wall blocks, floor blocks, embankment blocks, interlocking blocks, curbstones and other blocks. Adding fabric devices can produce colored pavement bricks.

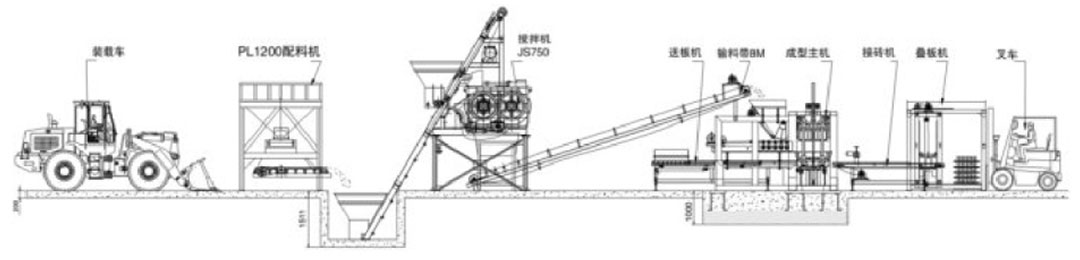

Installation base diagram

Production comparison table

| Name and picture |

Hollow Block |

Standard Solid Brick |

Porous Block |

Colored pavement Brick |

|

| Size | 390×190×190 | 240×115×53 | 240×115×90 | 200×100×60 | |

| QT18-15 | Number of molding blocks (blocks/mold) | 18 | 110 | 54 | 66 |

| Blocks produced per hour | 3375-4500 | 20625-27500 | 10125-13500 | 12375-16500 | |

| Blocks produced per 8-hour shift | 27000-36000 | 165000-220000 | 81000-108000 | 99000-132000 | |

| QT15-15 | Number of molding blocks (blocks/mold) | 15 | 84 | 40 | 55 |

| Number of blocks produced per hour | 2813-3750 | 15750-2 1000 | 7500-10000 | 7508-9528 | |

| 8-hour block/shift output | 22500-30000 | 126000-168000 | 60000-80000 | 60060-76230 | |

| QT12-15 | Number of molding blocks (blocks/mold) | 12 | 60 | 35 | 48 |

| Number of blocks produced per hour | 2160-2880 | 10800-14400 | 6300-8400 | 6912-8640 | |

| 8-hour blocks/shift | 17280-23040 | 86400-115200 | 50400-67200 | 55296-69120 | |

| QT10-15 | Number of molding blocks (blocks/mold) | 10 | 54 | 27 | 35 |

| Blocks produced per hour | 1800-2400 | 9720-12960 | 4860-6480 | 5040-6300 | |

| Blocks produced per 8-hour shift | 14400-19200 | 77760-103680 | 38880-51840 | 40320-50400 | |

| QT8-15 | Number of molding blocks (blocks/mold) | 8 | 42 | 18 | 28 |

| Number of blocks produced per hour | 1440-1920 | 7560-10080 | 3240-4320 | 4032-5040 | |

| 8-hour block/shift output | 11520-15360 | 60480-80640 | 25920-34560 | 32256-40320 | |

| QT6-15 | Number of molding blocks (blocks/mold) | 6 | 36 | 15 | 18 |

| Number of blocks produced per hour | 1080-1440 | 6480-8640 | 2700-3600 | 2592-3240 | |

| 8-hour block/shift production | 8640-11520 | 51840-69120 | 21600-28800 | 20736-25920 | |

Note: The above production table is a theoretical calculation value. Molding cycle and production volume are related to raw materials and product types.

Main technical parameter comparison table

|

Product model Product model |

Main engine size Main engine size |

Machine weight Machine weight |

Molding method Vibration type |

Molding cycle Cycle Time |

Installed capacity Capacity |

Vibration force | Pallet size |

| QT18-15 | 15500x5500x3200(mm) | 34(T) | Vibration compression molding | 15-23(S) | 104(KW) | 280(KN) | 1400x1400(mm) |

| QT15-15 | 11500x4550x2800(mm) | 20(T) | Vibration compression molding | 15-23(S) | 69.1(KW) | 220(KN) | 1350x1150(mm) |

| QT12-15 | 3300x2610x2750(mm) | 17(T) | Vibration pressure molding |

15-20(S) Colored bricks 20-25(S) |

125(KVA) | 75-120(KN) | 1350x860(mm) |

| QT10-15 | 3200x2510x2750(mm) | 11.8(T) | Vibration pressure molding |

15-20(S) Colored bricks 20-25(S) |

125(KVA) | 75-110(KN) | 1250x860(mm) |

| QT8-15 | 3200x2200x2750(mm) | 10.8(T) | Vibration pressure molding |

15-20(S) Colored bricks 20-25(S) |

100(KVA) | 55-75(KN) | 960x860(mm) |

| QT6-15 | 3100x3300x2700(mm) | 8.8(T) | Vibration pressure molding |

15-20(S) Colored bricks 20-25(S) |

80(KVA) | 50-70(KN) | 920x780(mm) |

Note: The product is constantly upgraded, and the technical parameters are subject to the actual product.

Previous Article:DW European series block making machine

Next Article:One-way static brick pressing machine series Return

Next Article:One-way static brick pressing machine series Return