The machine is equipped with a marshaling mechanism which can organize cement bricks into suitable specifications for loading, such as (900-1200mm). The bricks are pushed and grouped in a mechanical channel to achieve packing and leaving holes. It has relatively low requirements on the strength, shape and mold of cement bricks and has a relatively high overall applicability. The finished products can be packed and stacked with holes or transported by wooden brackets holding brick clamps./p>MORE

This palletizing production line is suitable for the palletizing of dry products of simple block production lines. It is a semi-automatic palletizing production line. Generally, it is independently set up near the product curing yard. For the on-site palletizing of the cured products, it can also be connected in series with the block production line to implement online palletizing./p>MORE

/p>MORE

/p>MORE

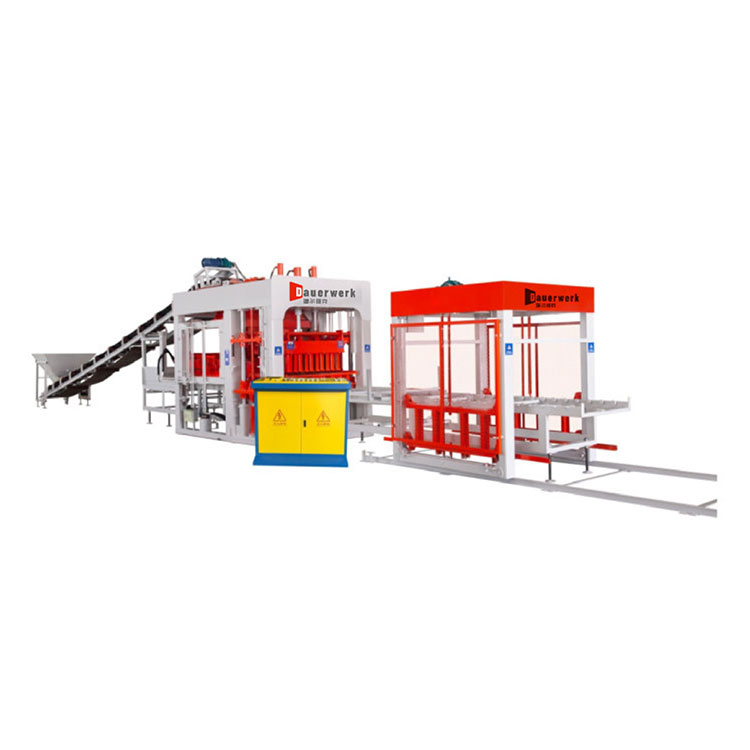

This equipment can produce high-strength pavement bricks with surface layer, curbstone bricks, etc. It adopts imported PLC control, realizes mechanical, electrical, liquid-integrated and automated, is equipped with human-machine interface, has automatic fault diagnosis, remote monitoring and other fully automatic operation procedures, and is used to press various PC imitation stone bricks, permeable bricks, wall bricks, curbstones, etc./p>MORE

Raw materials: sand, gravel, cement, and a large amount of fly ash, slag, steel slag, coal grinding stone, ceramsite, perlite and other industrial wastes can be added./p>MORE

Sales area

received honors

Industry experience

Compared with traditional clay brick machines, the raw materials of block forming machines can be selected from industrial waste slag: coal fly ash, coal gangue, slag, smelting slag and various tailings slag as the main raw materials, which is more environmentally friendly, energy-saving and waste recycling.

Simply put, palletizing robots should be classified as a type of palletizer.