Products

Recommended

Products

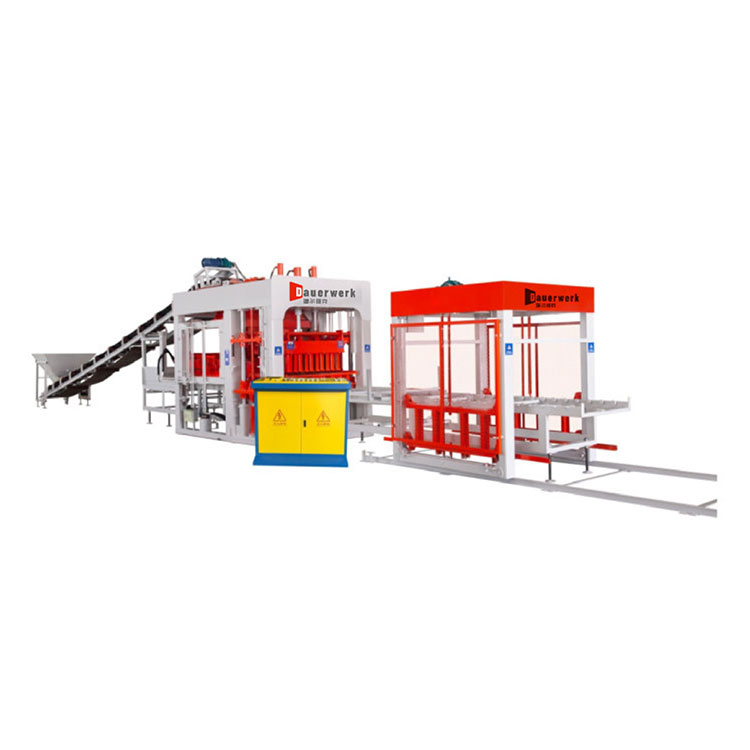

Current Location:Home > Products>Molding MachineBidirectional static brick press series

Building waste, sludge, slag, coal gangue, stone powder, slag and other materials are cured without burning to make bricksMain machine part (including hydraulic station, electric control box, plate feeder, brick discharging machine)

Raw materials: various slags, mineral powders and metal powders containing lead, zinc, copper, tin, etc. in the smelting industry.

Purpose: Utilize various solid wastes such as fly ash, phosphogypsum, tailings sand, sludge, construction waste, etc. to produce paving bricks, environmentally friendly unburned bricks, etc.

Main features

1. Static pressure molding, energy saving and high efficiency:

Pallet-free fully automatic static pressure molding, no pollution, low noise. A constant power variable pump is used to provide the power source for the system. The pump output energy is automatically adjusted according to the actual working conditions, and it is equipped with a more optimized hydraulic control system, making the whole machine more energy-saving and efficient;

2. Equivalent bidirectional pressurization and high yield rate:

The brick blank molding adopts the equivalent bidirectional pressurization method of main cylinder pressurization and demoulding cylinder follow-up. The brick blank has high density, good quality and high yield rate;

3. Advanced and reliable control system:

The closed-loop control technology of servo proportional valve, linear displacement sensor and servo motor is adopted, and the electronic control system is optimized and improved, with strong anti-interference ability, fast response, and precise pressure and position control;

4. Wide adaptability:

With a variety of optional material distribution methods and a large-stroke demoulding cylinder, the brick press can be used to form bricks of various raw materials and specifications.