Products

Recommended

Products

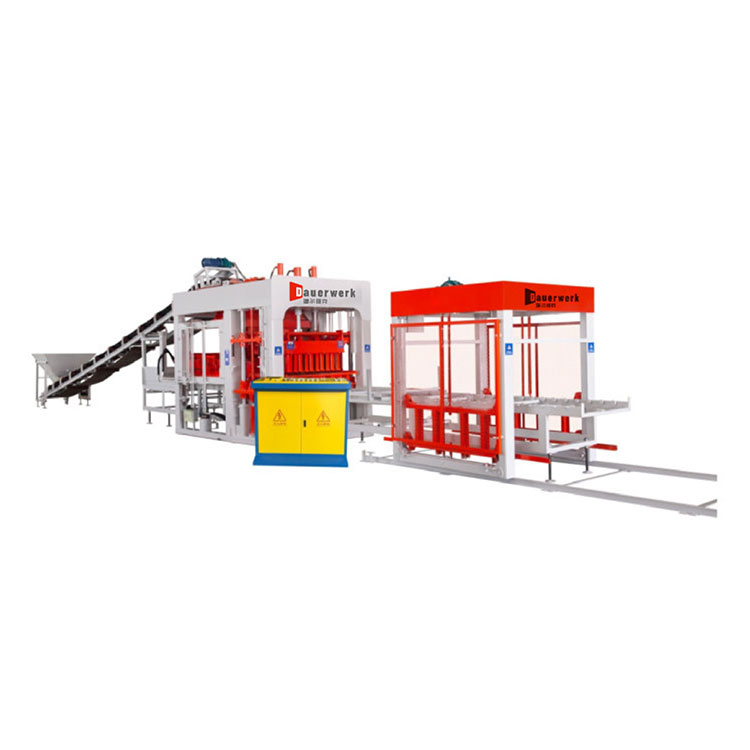

Current Location:Home > Products>Molding MachineCeramic foam concrete block equipment

The ceramsite self-insulating block equipment is a dual-purpose machine. It is used for large-scale production of ceramsite foam concrete blocks, ceramsite reinforced aerated blocks, cement foam bricks, foam concrete blocks, steam-free aerated blocks and other production line equipment. This set of equipment is a multi-purpose machine, used to produce load-bearing ceramsite reinforced aerated blocks and non-load-bearing self-insulating foamed concrete bricks. As well as exterior wall insulation boards, fire door core boards, etc. The entire production line has a small investment, which is only 20% to 2% of the traditional production line (high-pressure steam curing), with low production costs and low operating costs.

Features of foam concrete blocks and ceramsite self-insulating blocks:

Lightweight, high strength, can be nailed or hung, impermeable, fireproof, heat-insulating, sound-proof, simple, green and environmentally friendly, simple and beautiful

Features of foam concrete block equipment

Dolvik foam concrete block production line equipment has advanced technology and superior performance. The specific advantages are as follows:

➊The main raw materials for the production of foam concrete blocks are fly ash, ceramsite, lime and other industrial wastes. They are easy to obtain and cheap in China. The investment of the entire production line is small, which is only 20% to 2% of the traditional production line (high-pressure steam curing). Low production cost and low operating cost.

❷ Energy-saving advantage: The production line of this project saves energy and does not require traditional autoclave "steaming", which can greatly save electricity and coal.

❸ Process advantage: The use of composite additives will make the blocks have independent closed micropores, which will solve the problem of difficult control of the internal pore shape and pore rate of the blocks. It can greatly reduce the water absorption rate of the blocks and improve the anti-freeze and thaw performance, thereby ensuring product quality and eliminating product loss.

❹ Equipment advantage: The use of an automated control system makes the entire production line more reliable; at the same time, full CNC technology can be used to accurately measure the feed, high-speed stirring, and rapid foaming, simplifying the production process and saving manpower.

❺ Environmental protection advantage: The entire production process does not emit wastewater and smoke, is pollution-free, has low noise, and does not damage arable land.

Foam concrete block process flow

Foam concrete self-insulating block brick equipment has a simple and convenient operation from batching + mixing - + molding → demoulding - + cutting - + maintenance - → inspection and delivery. It has a large output and a high return on investment. It is a new type of environmentally friendly construction machinery production equipment.